|

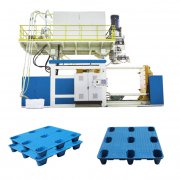

PXB120-IBC technical parameters |

|

Basic Specifications |

unit |

Specification |

|

using raw materials |

|

HMWHDPE |

|

Maximum product volume |

L |

1000 |

|

Production capacity (empty cycle) |

PC/HR |

100 |

|

Dimensions (L×W×H) |

M |

10.8×4.5×7.8 |

|

Mechanical weight |

T |

80 |

|

Mould opening and closing system |

|

|

|

Clamping force |

KN |

1500 |

|

Template spacing |

MM |

1000-2700 |

|

Template size |

MM |

1800×1600 |

|

Maximum die size (W×H) |

MM |

1600×1400 |

|

Die thickness |

MM |

1100-1500 |

|

power |

|

|

|

Maximum drive power |

KW |

300 |

|

Screw fan power |

KW |

2×1.5 |

|

Oil pump motor power |

KW |

2×18.5 |

|

Air pressure |

MPA |

1 |

|

Air source displacement |

M3/MIN |

4 |

|

average energy consumption |

KW |

250 |

|

Extrusion system |

|

|

|

Screw diameter |

MM |

2×120 |

|

Screw aspect ratio |

L/D |

30 |

|

Plasticizing capacity (HDPE) |

KG/H |

2×400 |

|

Number of screw heating sections |

ZONE |

2×6 |

|

Screw heating power |

KW |

2×55.8 |

|

Extrusion motor power |

KW |

2×132 |

|

die |

|

|

|

Number of die heating sections |

ZONE |

7 |

|

Die head heating power |

KW |

91.7 |

|

Maximum diameter of extrusion port |

MM |

650 |

|

storage tank volume |

L |

60 |

Basic configuration:

Electronic control system: PLC control system made by MITSUBISHI in Japan, 10 inches colourful touch screen control system made in Taiwan, all-round realization of process parameter setting, retrieval, monitoring, fault diagnosis; Mitsubishi 4AD temperature control module, integrated and precise control of temperature changes, reliable performance, long lasting;

Hydraulic system: Taiwan or Germany Servo oil pump motor + Japanese Sumitomo pump, equipped with Taiwan hydraulic components, proportional pressure control, the whole machine operates smoothly, responds quickly and efficiently, and reduces equipment energy consumption and noise significantly;

Mould opening and closing system: Double horizontal movement + ball linear guide + beam wall cylindrical shaft + center clamping, with high-precision rack and pinion, to ensure efficient and stable mold opening and closing; large oil cylinder pressurized clamping to ensure greater clamping force

Extrusion system: Hard tooth surface reducer + ABB inverter + Siemens motor + special optimized screw for blow molding, to ensure the perfect plasticization of various raw materials, ensure the screw extrusion volume per unit time, efficient and stable speed regulation, low noise, high efficiency energy saving;

Die head system: made of special steel, optimized flow design, center feed extrusion die head, eliminate the merge line, improve product performance;

Wall thickness system: Japanese MOOG 100 points wall thickness controller + Use the most advanced product surface thickness controller in China to control accuracy is 0.05-20MM, which perfectly realizes the precise control of various products;

Hot Tags: china blow molding machine maker,suppliers, manufacturers, factory,zhangjiagang,China, customized

Related Products

Relative Articles

+86-18958612836

+86-18958612836